Primarily differences are due to their different chemical bonding properties homework 1.

Stress strain curve of metal ceramic polymers.

Metallic infrastructure for metal ceramic crown.

Therefore it is used in many coating applications for example metal working industry.

Now that you have been introduced to the mechanical behavior of ceramics please go to your e textbook and read more on this topic on pages 84 to 86 in chapter 4 of materials for today s world custom edition for penn state university.

Elastic materials strain when stretched and immediately return to their original state once the stress is removed.

The utility of stress strain tests for design with polymeric materials can be greatly enhanced if tests are carried out over a wide range of temperatures and strain rates.

A highly elastic polymer may stretch over 10 times the original length before breaking while a metal might elastically stretch 10 of the original length elastically and may stretch.

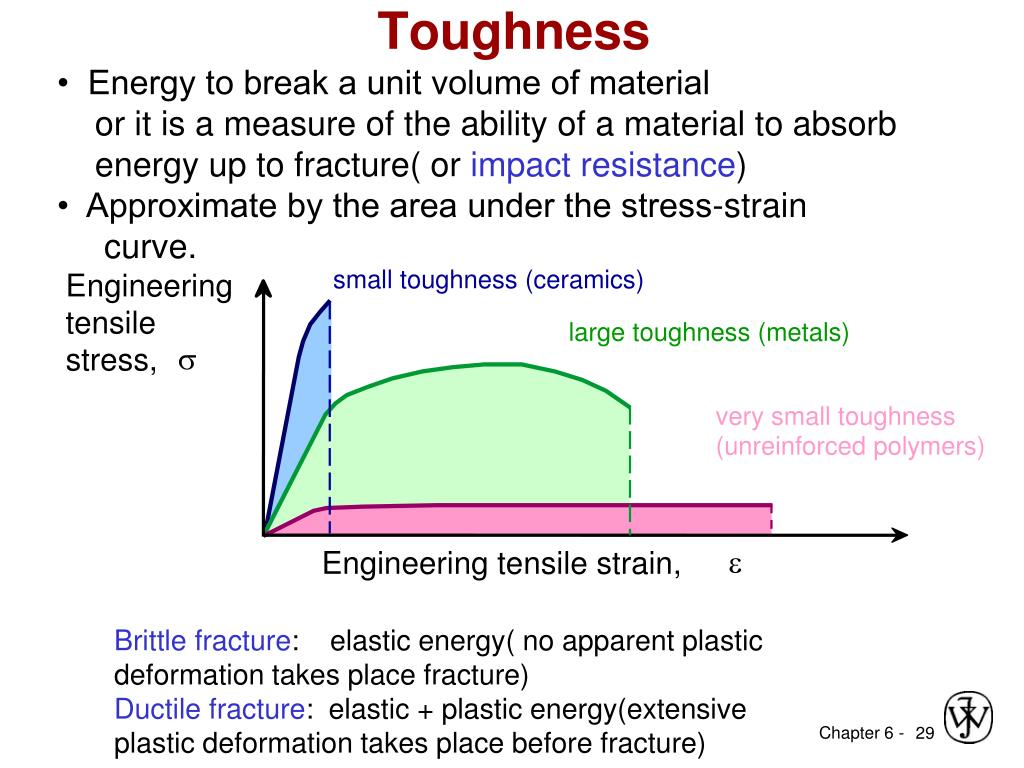

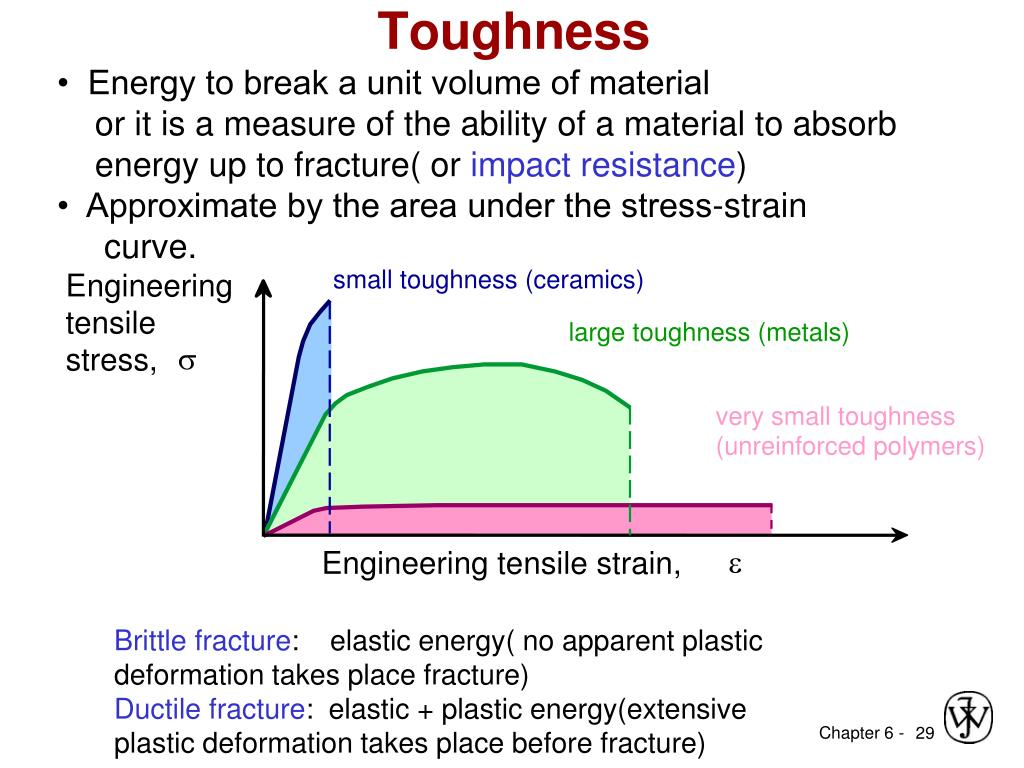

Stress strain curves for metals ceramics and polymers objective we are interested about studying and comparing stress strain curves of metals ceramics and polymers.

A characteristic yield point is shown followed by a strength drop that breaks at low stress and high strain.

Viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation viscous materials like water resist shear flow and strain linearly with time when a stress is applied.

Given materials are ductile polymer ductile metal ceramic glass and natural rubber.

After plotting the stress and its corresponding strain on the graph we get a curve and this curve is called stress strain curve or stress strain diagram.

While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics.

In this the stress is plotted on the y axis and its corresponding strain on the x axis.

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

Alloys ceramic and polymer thin films onto a wide range of substrate materials.

Strain stress experiments polymers exhibit a wide variation of behavior in stress strain tests ranging from hard and brittle to ductile including yield and cold drawing.