For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

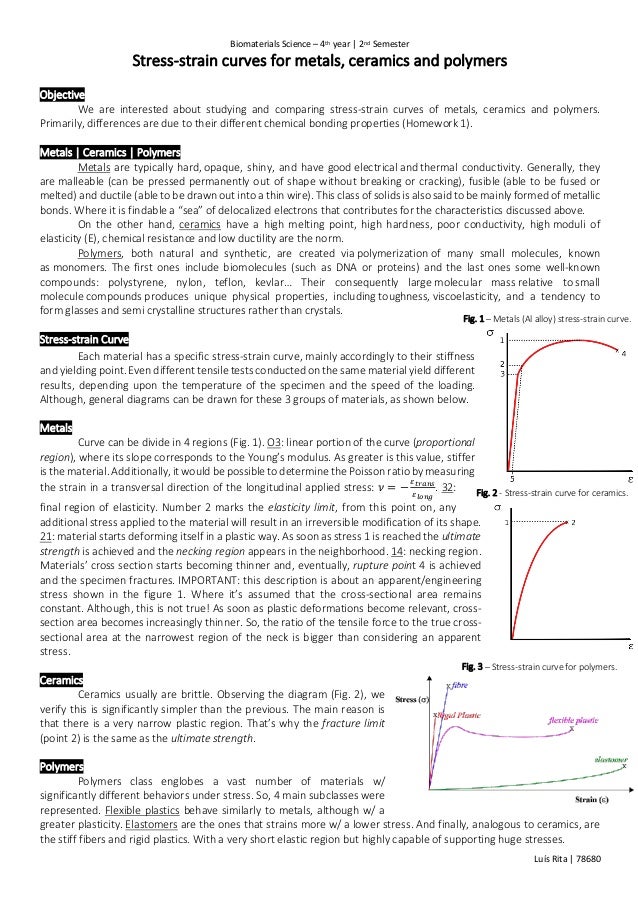

Stress strain graph for ceramics.

Stress strain curve for this material is plotted by elongating the sample and recording the stress variation with strain until the sample fractures.

7 18 callister rethwisch.

With a very short elastic region but highly capable of supporting huge stresses.

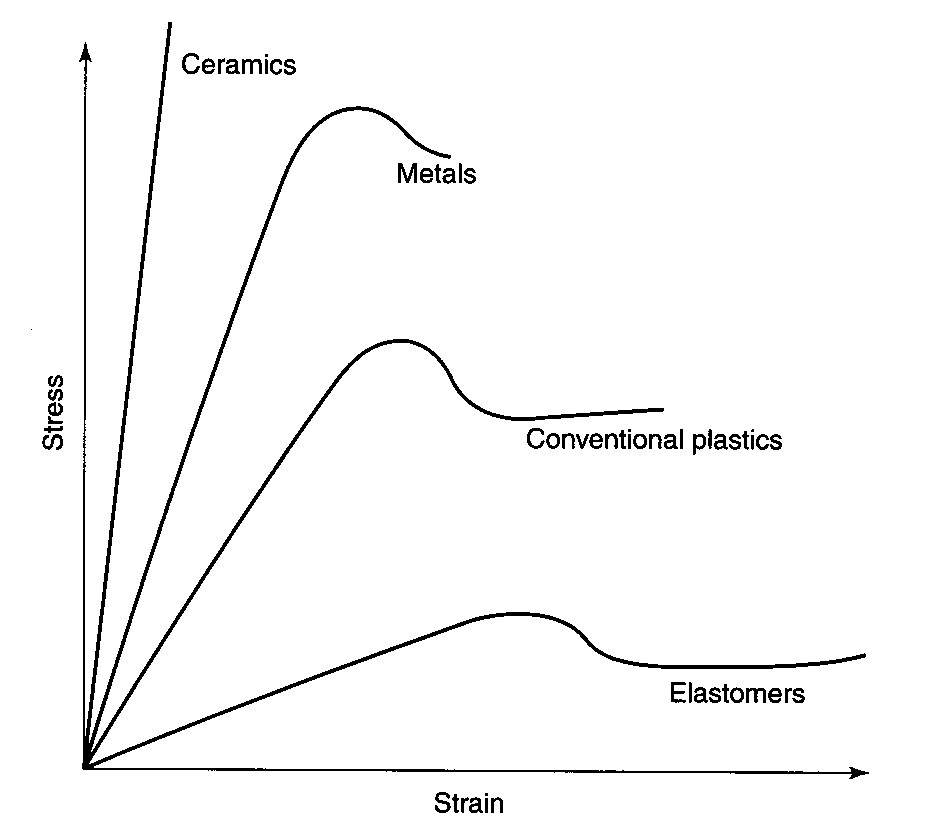

Stress strain behavior of polymers.

By convention the strain is set to the horizontal axis and stress is set to vertical axis.

While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics.

Stress strain graphs allow us to describe the properties of materials and also to predict the stresses at which changes in these properties might occur this graph compares the stress strain graphs for four different materials.

After plotting the stress and its corresponding strain on the graph we get a curve and this curve is called stress strain curve or stress strain diagram.

Mechanical properties of polymers.

7 22 callister rethwisch 5e.

The electric strain gauge was used to study the deformation of several types of ceramic materials under stress.

Ceramics are extremely strong and have very high uts values.

A ductile material shows a characteristic yield point followed by a drop in strength and break at lower stress but much higher strain.

And finally analogous to ceramics are the stiff fibers and rigid plastics.

Materials with high plasticity show strong necking and in some cases cold drawing.

2 stress strain curve for ceramics.

At this point the material starts to undergo plastic deformation.

Stress strain curve is the plot of stress and strain of a material or metal on the graph.

Ceramic steel glass and copper.

In this the stress is plotted on the y axis and its corresponding strain on the x axis.

Elastomers are the ones that strains more w a lower stress.

It is a widely used reference graph for metals in material science and manufacturing.

There are various sections on the stress and strain curve that describe different behaviour of a ductile material depending on the amount of stress induced.

Predict the type of material suitable to be used to reduce the effect of sudden impact.

The hard fired materials exhibit straight line deformation to failure while the softer fired have a proportional elastic limit beyond which the stress strain curve deviates.

1 metals al alloy stress strain curve.

Three point bending apparatus used determine stress strain behavior.